Die Cut, Perf Cut, Kiss Cut - What are they? Affect me how?

Posted by Karen Gendron on 27th Sep 2018

Stickers require cutting prior to being distributed to the customer. Sticker vinyl (outdoor vinyl, wall sticker vinyl) comes on large 50 yard rolls (depending on the type of machine the stickers are being printed on). These rolls are placed into the printing machine, and once printed, must be cut down. Whether cutting via plotter, laser, or hand, there are different ways that stickers can be cut: die cut or kiss cut.

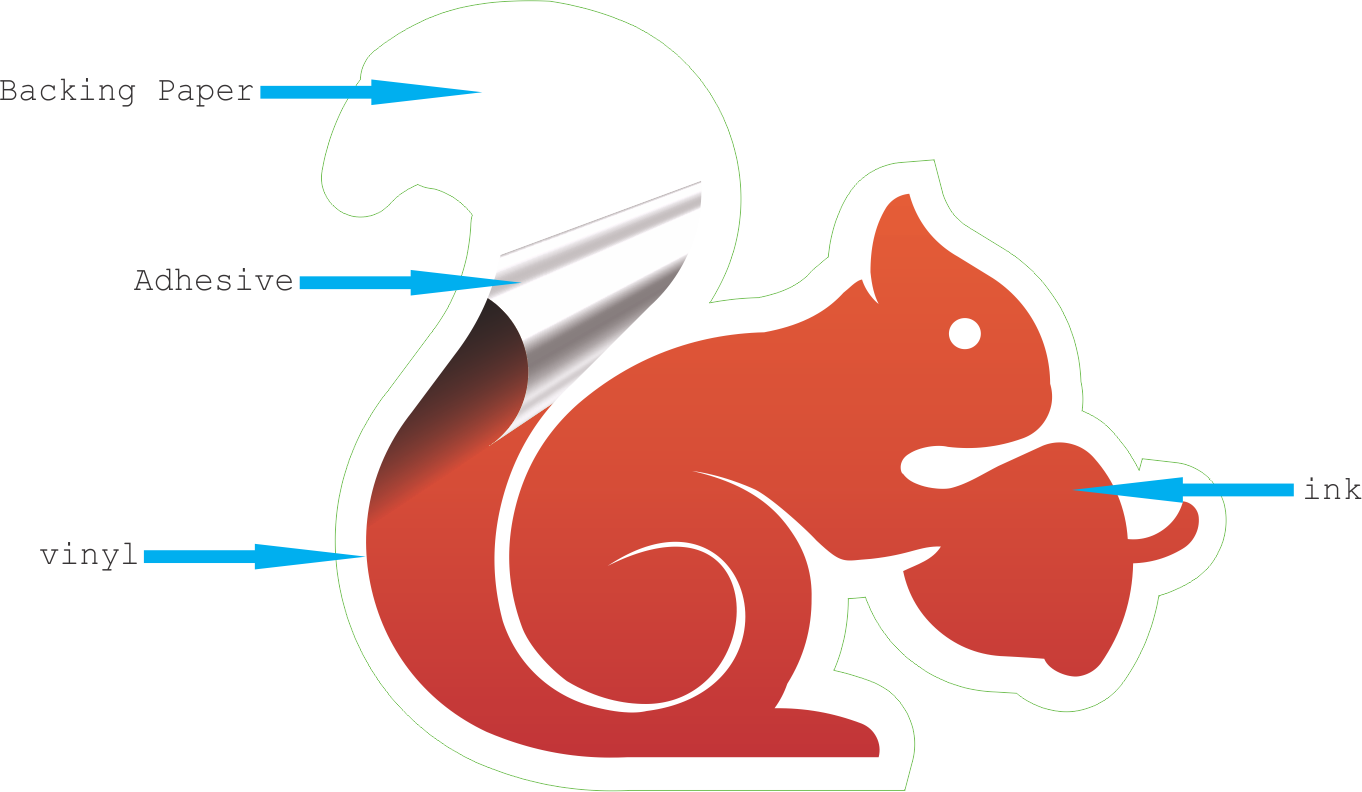

Sticker Breakdown:

Stickers are made of four components:

1. Ink that makes the image

2. Vinyl material which the ink sticks to

3. Adhesive that makes the vinyl sticky

4. Backing that protects the adhesive.

What is a Die Cut Sticker?

Die cuts refer to an old technology that uses metal dies to cut through stacks of paper or vinyl. Dies can cut hundreds if not thousands of stickers at one time. A traditional die is expensive to tool and is usually only used for very large orders.

Newer technology allows either a knife (plotter) or a laser to cut stickers. Without using a die, they are technically not "die cut". However, the term is still used, and refers to the same effect of cutting around the edge of the sticker through the backing.

Another term that is equivalent, and probably more appropriate, is a perforated (Perf) cut. This refers to the same effect of cutting around the edge of the sticker, and we use the term interchangeably with die cut.

What is a Kiss Cut Sticker?

A kiss cut refers to a cut through the vinyl layer to “kiss” the backing paper. This cut does not cut all the way through the backing paper.

We are normally so precise that an indentation is seen on the surface of the backing paper that indicates where the blade skimmed the surface (this is what should be seen).

The Difficulty with Die Cut

When we die (perf) cut, we are cutting through the entire sticker: backing and vinyl front. It can be difficult for the blade to make tight turns. As a result, any radius under 1/4” may be a less than perfect edge.

We encourage our customers to make simple shapes for their die cuts as it makes for a better product.

Kiss Cut to the Rescue

The sky is the limit with a kiss cut. The blade is traveling through a much thinner material (vinyl layer only) so it can make very precise cuts.

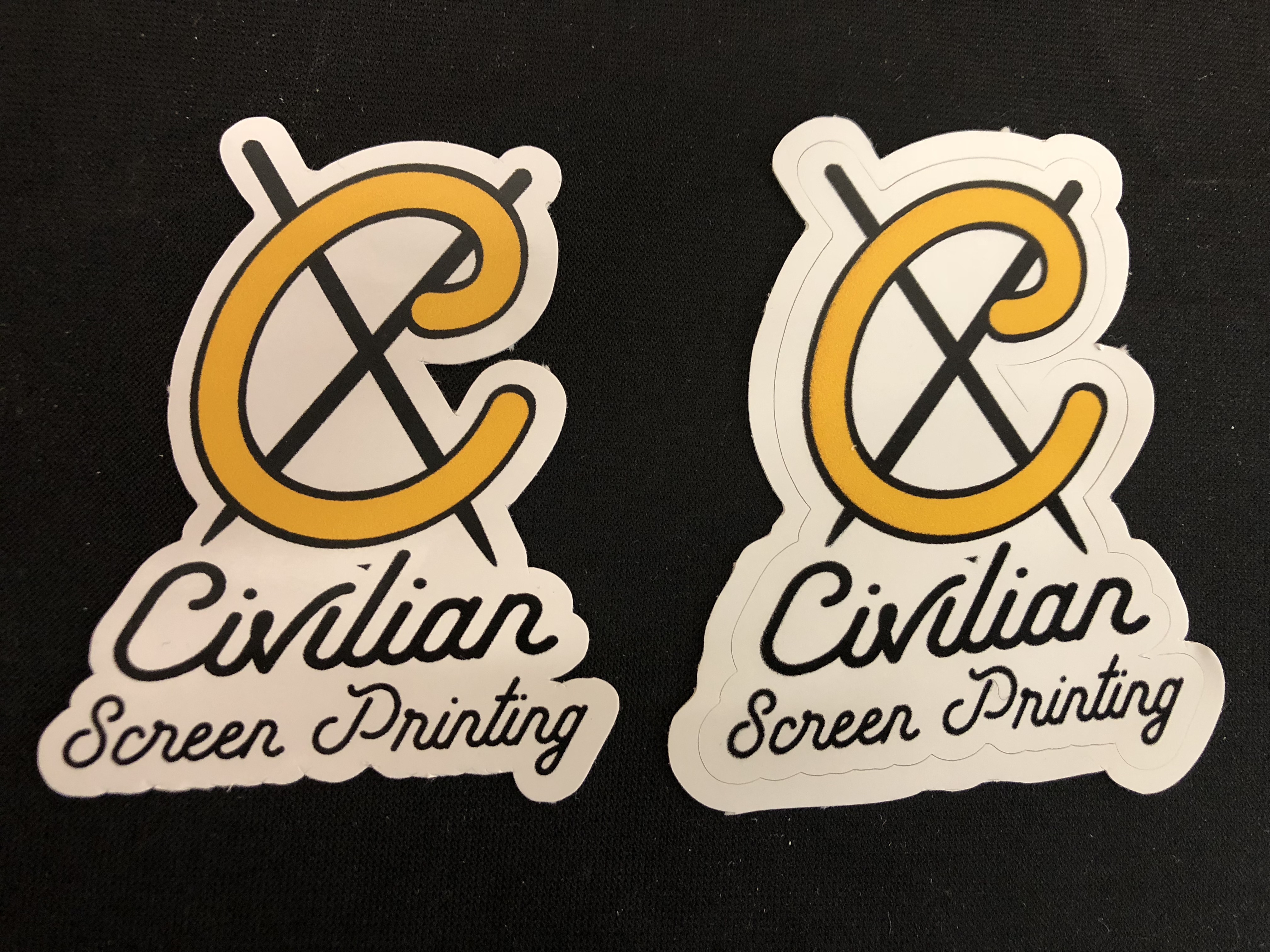

Do you have an intricate design that you would like to be a die cut sticker, but is just too small or too intricate?

We suggest doing a combination of the two cuts, as seen in the example above. Make a kiss cut that can be as intricate as you want. Then, make a slightly larger (3 - 4mm) die cut that is a simpler shape. This not only makes an amazing looking decal but also aids in peeling off the decal from the backing, because you don’t have to peel from the edge.

Let us know if you would like help creating these cut lines. It is a free service with the purchase of your stickers.

Sticker Sheets

Due to the precision of our kiss cuts, our sticker sheets are phenomenal. Check out some of the sticker sheets we have done on our instagram and start planning yours! They are the biggest bang for your buck because there is no limit to the number of cuts or stickers you can get out of the sheet.

Please note: we do require cut lines on stickers sheets to be provided by the customer.